Flex

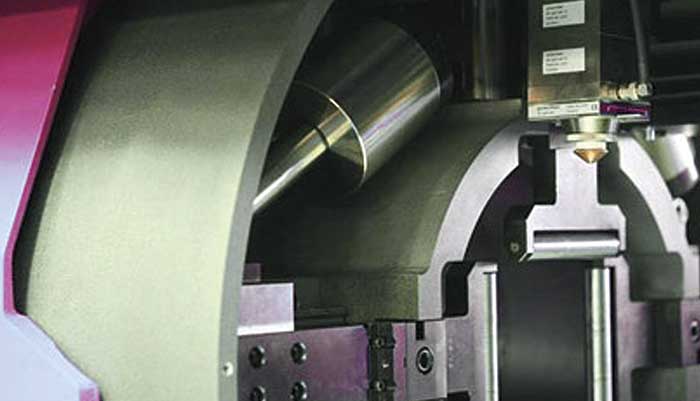

Tubes, profiles and systems are everywhere. They're used for everything from mechanical engineering to system construction to furniture making. With the new possibilities that lasers present, designers are increasingly taking advantage of laser-cut tubes or profiles. This has led to a substantial increase in demand. TruLaser Tube machines are a complete solution for laser tube cutting.

When it comes to processing tubes, pipes, and structural steel, Gulf States Saw & Machinery Co., Inc. has a solution to fit a range of fabrication needs. Not only do Gulf States Saw & Machinery Co., Inc. tube lasers offer superior laser-cutting technology, many also integrate additional processing functions to deliver value-added benefits for fabricators.